weld symbols pdf

Weld symbols are standardized representations used to communicate welding requirements clearly․ They include elements like the basic weld symbol, reference line, and tail, ensuring consistency across designs․ PDF guides detail AWS, ISO, and BS EN 22553 standards, providing diagrams and specifications for accurate application in technical drawings and manufacturing processes․

Overview of Weld Symbols and Their Importance

Weld symbols are essential for clear communication in manufacturing and construction, providing detailed welding instructions․ They ensure consistency and accuracy, reducing errors in fabrication․ These symbols represent weld types, sizes, and locations, guiding technicians and engineers․ Standards like AWS, ISO, and BS EN 22553 define their use, ensuring universal understanding․ Weld symbols are critical for project success, as they clarify requirements and prevent misinterpretation․ They are integral to blueprints and work instructions, enabling efficient and precise execution of welding tasks across industries like automotive, aerospace, and construction․ Their importance lies in maintaining quality, safety, and compliance with design specifications․

Standards Governing Weld Symbols (AWS, ISO, BS EN 22553)

Weld symbols are governed by international standards to ensure clarity and consistency․ The AWS A2․4 standard provides comprehensive symbols for welding, brazing, and nondestructive examination․ ISO 2553 is the international standard, offering universal guidelines for weld symbols․ BS EN 22553 is the British and European standard, aligning with ISO 2553 to maintain harmony across Europe․ These standards define the basic elements of weld symbols, such as the reference line, arrow, and tail, ensuring precise communication of welding requirements․ They also specify how to indicate weld types, sizes, and locations․ Adherence to these standards is crucial for avoiding errors and ensuring compliance with design specifications in global manufacturing and engineering projects․

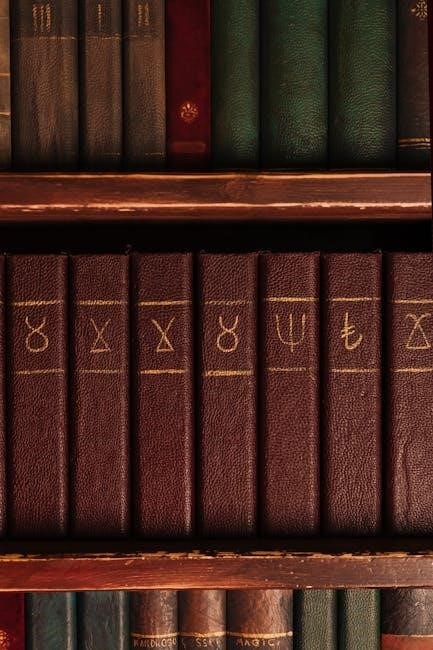

Types of Welds and Their Symbols

Fillet, groove, plug, and spot welds each have distinct symbols․ These are detailed in weld symbols PDF guides for clear identification and application in engineering designs․

Fillet Welds

Fillet welds are among the most common types of welds, joining two surfaces at a right angle․ Their symbols are detailed in weld symbols PDF guides, such as AWS A2․4 and ISO 2553․ The fillet weld symbol is represented by a right triangle, with the right angle pointing toward the direction of the weld․ The size of the fillet is indicated by a number placed alongside the symbol, representing the weld’s throat thickness․ The symbol’s orientation relative to the arrow line signifies the weld’s location on the joint․ Supplementary symbols, such as the contour or melt-through indicators, may be added to specify surface finish requirements․ Fillet welds are widely used in structural steel and sheet metal fabrication due to their simplicity and strength․

Groove Welds

Groove welds are used to join two edges of metal parts by fusing the surfaces along a groove․ Common types include square, V, and bevel groove welds․ The symbol for groove welds varies based on the joint type, such as a square for square groove or a V-shape for V-groove welds․ The weld size is indicated by a number next to the symbol, representing the depth of penetration required․ Supplementary symbols, like the contour or melt-through indicators, may be added to specify finish or full penetration․ Groove welds are critical in applications requiring high strength and are detailed in standards like AWS A2․4 and ISO 2553, ensuring precise communication in technical drawings and manufacturing processes․

Plug Welds

Plug welds are used to join overlapping edges of two components, creating a strong, permanent bond․ The weld symbol for plug welds is a circle, indicating a round weld pool․ The size of the plug weld is specified by a number placed near the symbol, representing the weld’s diameter․ Supplementary symbols, such as a depth or finish indicator, may be added to provide additional details․ Plug welds are commonly used in structural applications where strength and integrity are critical․ Standards like AWS A2․4 and ISO 2553 provide detailed guidelines for representing plug welds in technical drawings, ensuring clarity and consistency in communication between designers and fabricators․ This ensures accurate interpretation and execution of the welding process․

Spot Welds

Spot welds are a type of resistance welding used to join overlapping sheets of material, typically metals․ The weld symbol for spot welds is represented by a circle with a cross at the center, indicating the weld’s location․ The size of the spot weld is specified by a number placed near the symbol, denoting the diameter of the weld․ Spot welds are commonly used in automotive and aerospace industries for joining thin-gauge materials․ Standards such as AWS A2․4 and ISO 2553 provide detailed guidelines for representing spot welds in technical drawings․ Supplementary symbols may indicate the number of welds or specific locations; This ensures clear communication between designers and fabricators, facilitating precise and efficient welding operations․

Understanding the Welding Symbol

A welding symbol is a detailed representation of weld requirements, including type, size, and location․ PDF guides like AWS A2․4 and ISO 2553 provide standard references for interpreting these symbols, ensuring clarity in technical drawings and manufacturing processes․

Basic Elements of a Welding Symbol

The welding symbol consists of three primary components: the arrow line, reference line, and tail․ The arrow line points to the joint, indicating where the weld is required․ The reference line serves as a baseline for adding supplementary symbols, such as weld type (e․g․, fillet or groove welds) and size․ The tail often contains additional information like the weld process or specifications․ Supplementary symbols may include weld type, contour, and finishing requirements․ These elements work together to provide precise instructions for welders and fabricators․ PDF guides, such as those from AWS A2․4, ISO 2553, and BS EN 22553, detail these components, ensuring consistency and clarity in technical drawings and manufacturing processes․

Location Significance in Weld Symbols

The location of elements in a welding symbol determines the weld’s placement and characteristics․ The arrow line points to the joint, indicating where the weld is required․ Symbols above the reference line specify welds on the arrow side, while those below apply to the opposite side․ When symbols appear on both sides, welding is required on both․ The tail may include process identifiers or special instructions․ Supplementary symbols, such as for contour or finishing, are placed adjacent to the reference line․ Proper placement ensures clarity and accuracy․ PDF guides like AWS A2․4, ISO 2553, and BS EN 22553 detail these rules, ensuring consistency in interpreting weld symbols for fabrication and quality control․

Standards for Weld Symbols

Key standards include AWS A2․4, ISO 2553, and BS EN 22553, providing detailed guidelines for weld symbols․ These standards ensure uniformity and clarity in technical drawings․ PDF guides are essential resources for understanding and applying these specifications accurately in engineering and manufacturing․

AWS A2․4 Standard Symbols for Welding, Brazing, and Nondestructive Examination

The AWS A2․4 standard provides comprehensive symbols for welding, brazing, and nondestructive examination․ It serves as the official guide for representing welds in technical drawings, ensuring clarity and consistency․ The standard includes detailed diagrams and specifications for various weld types, such as fillet, groove, and plug welds․ It also covers supplementary symbols for finishing operations like grinding or machining․ PDF versions of this standard are widely available, offering engineers and fabricators a portable reference․ By adhering to AWS A2․4, professionals can accurately communicate welding requirements, reducing errors and ensuring compliance with industry practices․ This standard is indispensable for maintaining precision and uniformity in manufacturing and engineering projects․

ISO 2553 Standard for Weld Symbols

ISO 2553 is the international standard for weld symbols, providing a unified system for representing welding requirements in technical drawings․ It includes symbols for various weld types, such as fillet, groove, and plug welds, as well as supplementary symbols for processes like brazing and soldering․ The standard also specifies conventions for indicating weld sizes, positions, and finishes․ PDF versions of ISO 2553 offer detailed diagrams and examples, making it easier to apply the standard in design and manufacturing․ This standard is widely adopted globally and is often used in conjunction with other standards like BS EN 22553 and AWS A2․4․ Its clarity and precision help reduce errors and ensure compliance with international engineering practices․

BS EN 22553 British Standard for Weld Symbols

BS EN 22553 is the British standard for weld symbols, aligning with ISO 2553 for international consistency․ It provides detailed specifications for weld types, including fillet, groove, and plug welds, as well as supplementary symbols for brazing and soldering․ The standard outlines conventions for indicating weld sizes, positions, and finishes, ensuring clarity in technical documentation․ Available in PDF format, BS EN 22553 is a vital resource for engineers and manufacturers, offering precise guidance for accurate symbol application․ It complements standards like AWS A2․4 and ISO 2553, promoting uniformity in engineering practices globally․ This standard enhances communication and reduces errors in design and production processes․